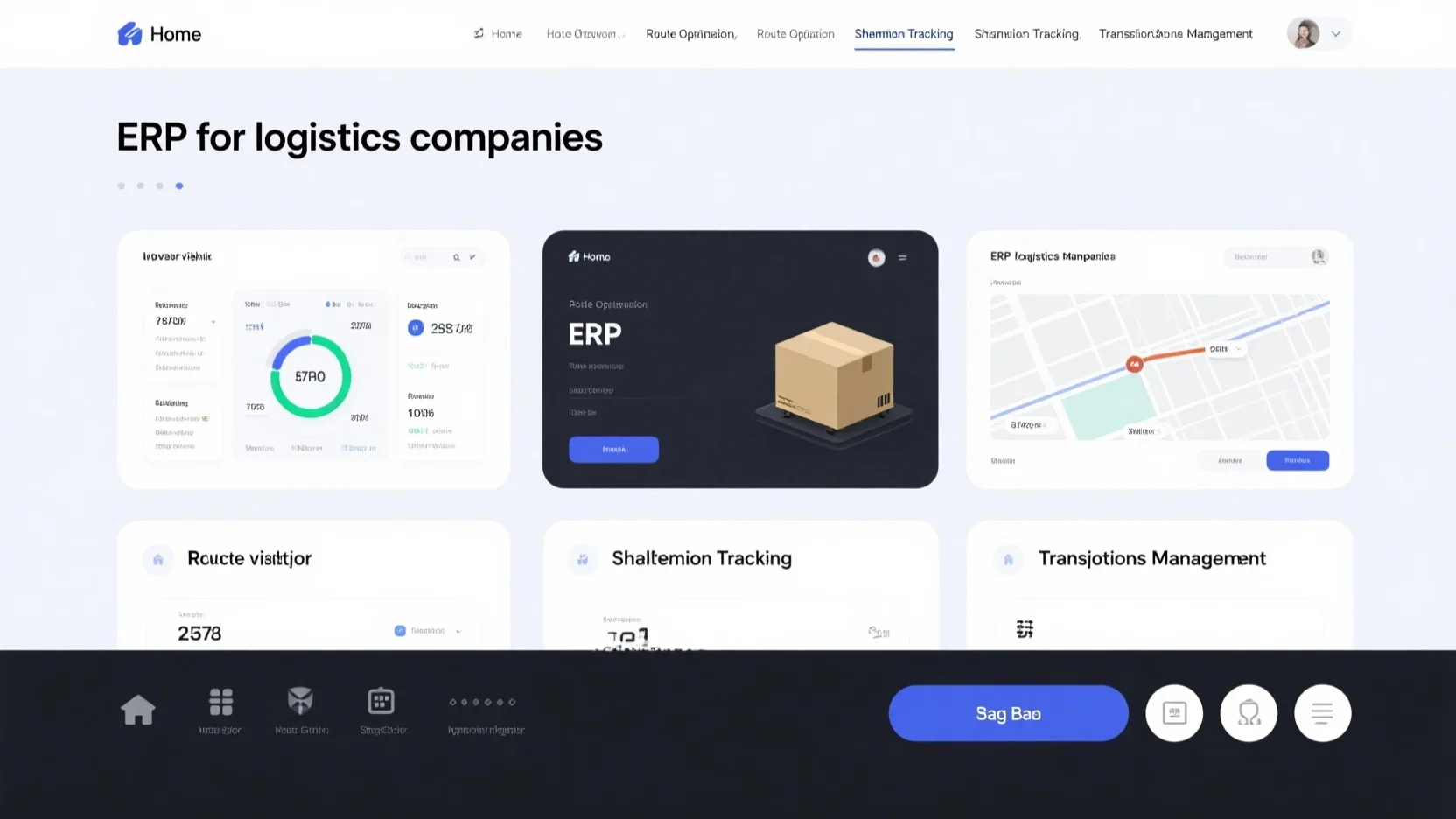

Are you a logistics company searching for the best ERP solution? Look no further! According to a SEMrush 2023 study, the logistics ERP system market is set to reach $78.4 billion by 2026, highlighting its growing importance. Premium ERP systems offer seamless transportation management integration, real – time inventory dashboards, and advanced route optimization. In contrast, counterfeit or subpar models may cause compatibility issues and data flow problems. With our guide, get a Best Price Guarantee and Free Installation Included, making it the perfect time to upgrade.

General information

Technologies for transportation management integration

The market for logistics ERP systems is booming, with projections reaching $78.4 billion by 2026 (SEMrush 2023 Study). These systems are crucial for streamlining logistics and reducing operational costs.

Automation in integration

Automation plays a vital role in transportation management integration. For example, an AI – powered system can automatically adjust delivery routes based on real – time traffic conditions. Pro Tip: Implement automated order processing in your ERP system to reduce manual errors and speed up the order – to – delivery cycle. By using technologies that automate repetitive tasks, such as generating shipping labels or updating inventory levels, companies can save time and improve accuracy.

Data integration for seamless information flow

Integrating data from various systems like ERP, WMS (Warehouse Management System), and TMS (Transportation Management System) is essential but can be challenging. However, when done correctly, it enables seamless information flow. For instance, when an order is created in the ERP system, data can flow directly to the TMS for further processing. This integration allows for better decision – making based on real – time data. Top – performing solutions include middleware software that can connect disparate systems and facilitate data transfer.

Implementation process

Implementing an ERP system comes with its own set of challenges, but understanding them can help companies plan better.

Cost – related challenges

Cost is a significant hurdle in ERP implementation. The initial investment in software licenses, hardware, and implementation services can be substantial. A practical example is a medium – sized logistics company that underestimated the cost of customizing an ERP system to fit its specific needs and ended up over budget. Pro Tip: Conduct a thorough cost – benefit analysis before starting the implementation process. Consider not only the upfront costs but also the long – term savings in operational efficiency.

Employee resistance

Employees may resist the implementation of a new ERP system due to fear of change or lack of training. For example, workers who are used to manual processes may be hesitant to switch to an automated system. To overcome this, companies should provide comprehensive training and involve employees in the implementation process from the beginning. As recommended by industry experts, start with a pilot project where a small group of employees can test the system and provide feedback.

System – related challenges

Integrating an ERP system with existing systems can be complex. There may be compatibility issues, and managing large volumes of data can be overwhelming. For instance, integrating an ERP system with legacy software may require significant programming work. Pro Tip: Simplify metrics and focus on key indicators to manage the data more effectively.

Contribution to efficiency and cost – reduction

ERP systems contribute significantly to efficiency and cost – reduction in logistics companies. By optimizing routes, minimizing unnecessary mileage, and reducing fuel consumption, companies can achieve substantial cost savings. A case study shows that a transportation company was able to reduce fuel consumption by 15% after implementing an AI – powered route optimization module in its ERP system. These systems also improve fleet management, enabling companies to meet delivery demands more efficiently, which in turn improves customer service and builds stronger customer relationships.

Key functions

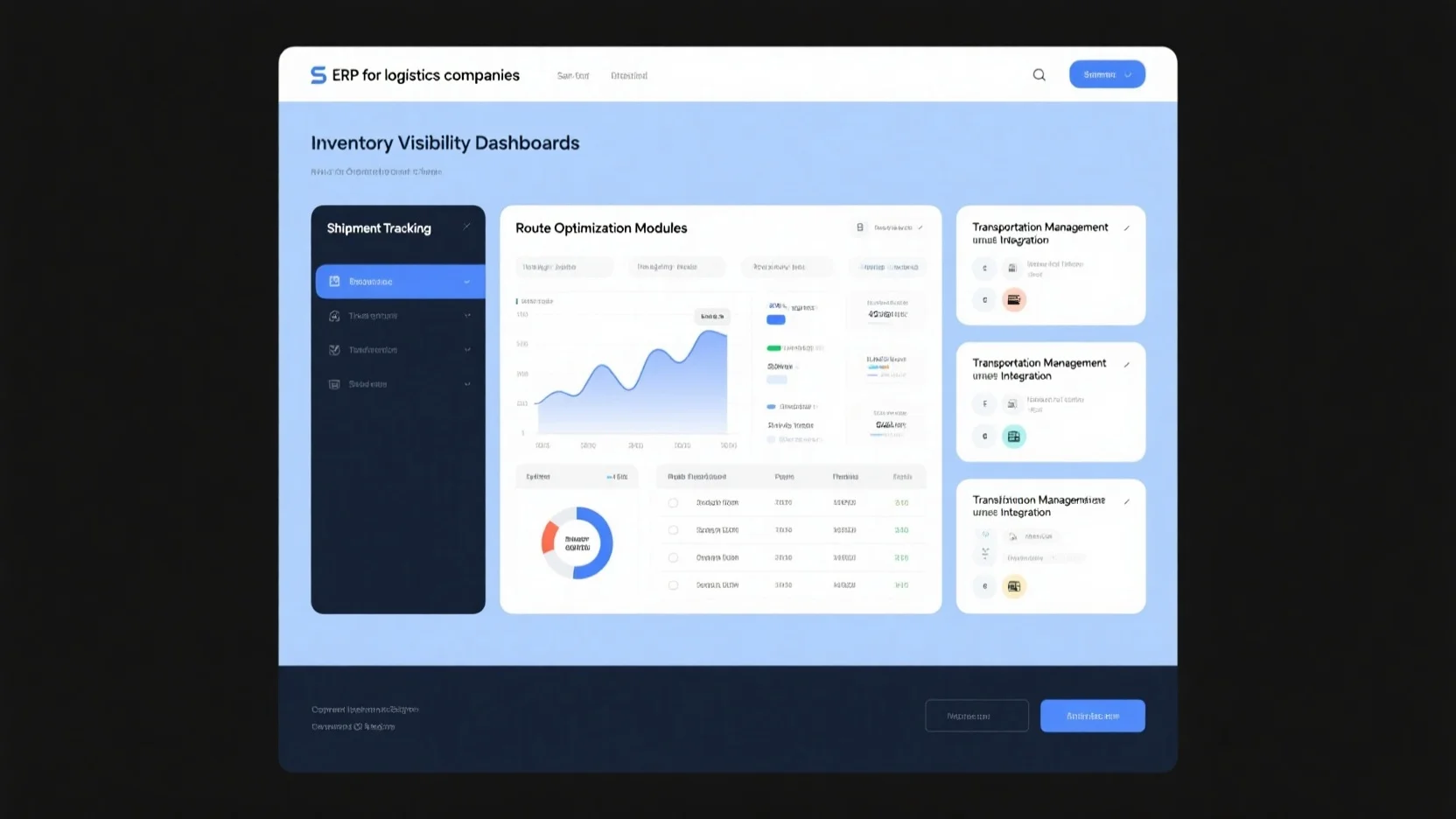

The key functions of an ERP system for logistics companies include order processing, fleet management, routing optimization, warehouse management, and billing. These functions are integrated into a single system, providing a holistic view of the logistics operations. For example, an inventory manager dashboard can provide real – time information on stock levels, fulfillment, and inventory in transit, which helps in making informed decisions.

Benefits of key functions

The benefits of these key functions are numerous. Real – time inventory visibility allows businesses to optimize stock levels, lower costs, and enhance customer satisfaction. Route optimization reduces fuel consumption and delivery times, improving overall operational efficiency. Pro Tip: Leverage tools like ePROMIS Inventory Management to gain insights from your inventory data.

Typical implementation process

A successful ERP implementation requires a strategic approach. It should start with a clear understanding of the business goals and requirements. The steps usually involve selecting the right ERP system, customizing it to fit the company’s needs, migrating data, and providing training to employees.

- Define your business goals and requirements.

- Research and select an appropriate ERP system.

- Plan the customization and integration process.

- Migrate data from existing systems.

- Train employees on how to use the new system.

- Conduct a pilot test before full – scale implementation.

- Monitor and evaluate the system’s performance.

Key Takeaways:

- Logistics ERP systems are projected to reach $78.4 billion by 2026.

- Automation and data integration are key technologies for transportation management integration.

- ERP implementation faces challenges such as cost, employee resistance, and system – related issues.

- ERP systems contribute to efficiency and cost – reduction through functions like route optimization and inventory management.

- A strategic approach is required for a successful ERP implementation.

Try our ERP implementation cost calculator to estimate the costs involved in your project.

FAQ

What is an ERP system for logistics companies?

An ERP system for logistics companies is a comprehensive software solution. It integrates functions like order processing, fleet management, and warehouse management. According to industry trends, it offers real – time inventory visibility and route optimization. This system streamlines operations, enabling better decision – making. Detailed in our Key functions analysis, it provides a holistic view of logistics operations.

How to implement an ERP system in a logistics company?

Implementing an ERP system in a logistics company requires a strategic approach:

- Define business goals and requirements.

- Research and select the right ERP system.

- Plan customization and integration.

- Migrate data from existing systems.

This process helps overcome challenges like cost and system compatibility. Professional tools required for this implementation can ensure a smoother transition.

ERP for logistics vs traditional logistics management: What’s the difference?

Unlike traditional logistics management, an ERP system for logistics offers real – time data integration and automation. Traditional methods often rely on manual processes, leading to errors and inefficiencies. An ERP system automates tasks like order processing and route adjustment. This results in better cost – reduction and operational efficiency, as detailed in our Contribution to efficiency and cost – reduction analysis.

Steps for overcoming employee resistance during ERP implementation?

According to industry experts, to overcome employee resistance during ERP implementation:

- Provide comprehensive training.

- Involve employees in the implementation process from the start.

- Start with a pilot project for feedback.

This approach helps employees adapt to the new system. Industry – standard approaches can make the transition less daunting and improve acceptance rates.